Submitted by ADPI® Center of Excellence (COE) team member Nana Farkye, PhD.

Click here for a PDF printable version of this article.

Cheese yield is simply the amount of cheese produced per pound of milk in a cheese vat. For standard of identity (SOI) cheeses, it depends on the efficiency of recovery of milk fat, milk proteins (primarily caseins), salts (including added salt) and the final moisture content of the cheese. For example, the SOI for Cheddar cheese requires that it must contain no more than 39% moisture and a minimum of 50% fat-on-dry basis (FDB). This means that the minimum wet fat content of Cheddar cheese is 30.5%. There is no upper limit for percent FDB for Cheddar nor is there a minimum moisture limit. However, there are suggested chemical composition ranges (Table 1), outside of which the cheese may be inferior and subject to defects during ageing. Low salt-in-moisture (S/M) influence starter activity in cheese and cheese flavor. Low pH results in acidic and crumbly cheese. Moisture in the nonfat substance (MNSF) influences cheese body. The composition ranges, suggested by New Zealand scientists hold true for commercial Cheddar cheese in the U.S. Nevertheless, the USDA Standards for grades of Cheddar cheese serve as a guideline for U.S. cheese manufacturers.

Table 1. Suggested chemical composition ranges for quality Cheddar cheese.

| Parameter | Good | Premium |

|---|---|---|

| FDB (%) | 50-56 | 52-54 |

| MNFS (%) | 52-57 | 52-56 |

| Salt-in-moisture (S/M) (%) | 2.5-6.0 | 4.0-6.0 |

| pH (%) | 4.95-5.1 | 4.85-5.2 |

For example, assume a manufacturer makes Cheddar cheese containing 30.5% fat and 38% moisture, the FDB for this cheese is 49% – making the cheese nonconformance to the SOI. This means that if the manufacturer targets 38% moisture in Cheddar, the manufacturer must target 31% fat in the cheese. Similarly, a manufacturer targeting 37% moisture in Cheddar must target a minimum fat content of 31.5% in the cheese. A manufacturer wishing to make premium Cheddar containing 54% FDB and 37% moisture must aim for 34% fat in Cheddar cheese. To optimize the fat content in the cheese means that the fat content of cheese milk must be controlled by standardization of milk to a constant protein (casein) to fat ratio. For Cheddar cheese, the ideal casein to fat ratio (C/F) is between 0.64-0.70 or protein to fat ratio (P/F) between 0.86-0.90 although standardization to C/F of 0.70 gives the most efficient fat recovery.

Standardization of Milk

Because milk composition varies seasonally and is influenced by feed (nutrition), health of cow (mastitis), stage of lactation of cows, somatic cell content, it is important to standardize milk for consistent cheese yields and quality.

To standardize cheese milk, the following are required:

- Accurately determine the fat and protein content of the milk.

- Determine the desired optimal total solids content in the cheese milk. The limitation of how much total solids in cheese milk depends on what the equipment (i.e., cheese vats, drain belt/table).

- Determine the method to use for standardization. Typical methods are a) removing fat from milk as cream or b) adding casein in the form of skim milk, nonfat dry milk, condensed skim milk or membrane concentrated milk (i.e., UF, RO or MF skim).

A plant must determine the most economical approach and method for standardization to maximize yields and plant efficiency.

Two approaches (in-line or silo) are used based on the plant schedule and equipment available. In-line standardization – also known as standardization “on the fly” is done by introducing known quantities of the liquid ingredient needed (e.g., cream, condensed or UF skim) in the milk in the balance tank during pasteurization. Accuracy in metering devices and time the ingredient is added to the balance tank by the operator is important. If the ingredient is introduced late, some of the ingredient may end up in the vat following the vat for which it is intended. Accurately blending large quantities of liquid or dry ingredients in milk in a silo presents challenges which are greater when nonfat dry milk is used because ample time must be allowed for powder dissolution and hydration. Other challenges when nonfat dry milk is used for standardization may be lumping and foaming leading to yield losses.

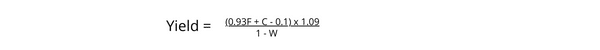

Theoretical cheese yield calculations are based the percentage fat (F), casein (C) in milk and the moisture (W) content of the cheese. Although several formulas have been proposed for calculating cheese yields, the traditional Van Slyke and Price equation below is simple and convenient.

which assumes the following:

- 93% of the milkfat is recovered in cheese,

- 0.1% of casein is lost in the whey

- Other constituents of milk plus the salt added to cheese represent 9% of the weight of fat and casein retained in the cheese.

Because there is no rapid test available for casein, the value of casein is estimated based on protein content of milk as 0.77× P for Holstein milk or 0.78× P for Jersey milk.

Cheese making factors that affect yield

Milk quality. Poor milk quality resulting from high somatic cell count and seasonal variation which affects the casein:whey protein ratio in milk.

Heat treatment. Minimum legal HTST pasteurization (161F × 15 s) of batch pasteurization (145F × 30 min) is traditionally used for cheese milk. High heat treatment causes denaturation of whey proteins which are trapped in the curd along with increased moisture during cheesemaking. Although cheese yield increase when whey proteins are trapped, cheesemaking must be adjusted to control moisture. Also, inclusion of high levels of whey proteins results affects cheese functionality such as melting and stretching when heated.

Homogenization. Homogenization is not normally used for cheeses such as Cheddar but are acceptable and often used for high moisture cheeses such as Hispanic cheeses and Feta. When used, it is advisable to use low homogenization pressures and one stage instead of two stage homogenization. Besides giving cheese a white appearance, homogenization of cheese milk results in soft rennet curd and relatively high moisture content of cheese.

Starter contribution to yield. Direct-to-vat innoculum (DVI) cultures used as starter add little to the yield of cheese because the amounts added is less than 0.1% of milk weight. Any contribution of DVI cultures to yield may be a result of moisture retention when exopolysaccharide-producing lactic acid bacteria are included in the culture blend. Bulk starters produced in-house may contribute to cheese yield when added at the rates od 2% of milk weight especially when made using high milk solids (e.g. casein).

Coagulant contribution to yield. The type and amount of coagulant (Chymosin) used contributes to yield by the structure and firmness of curd produced during casein hydrolysis during coagulation. Coagulants with high proteolytic activity produce high protein losses in the whey hence it is important to carefully select coagulant for cheesemaking. The amount of coagulant required to set the vat in 30 min depends on the strength of coagulant, setting temperature and pH of milk, and total solids (protein) content in the cheese milk. When acidic bulk starter is used, it is important to know the pH of milk and adjust coagulant accordingly. The amount of coagulant used must also be adjusted when cheese milk is pre-acidified.

The cutting intensity (i.e., duration of cutting, rate of cutting (speed of rotation of cutting knives) and the number of cycles affect curd size which in-turn affects cheese moisture. Large curd size results in higher moisture cheese than smaller curd sizes. Continuous cutting without cycling (stopping and starting knives) results in cut curds being pushed in front of the knives without further cutting.

Stirring and Cooking. Stirring and cooking facilitates syneresis and moisture loss from curd. The first operation to adjust when moisture targets are not met is cooking. Increasing cooking temperature by one degree will increase cheese moisture. Contrarily, decreasing cooking temperature by a degree will increase cheese moisture. In mechanized cheesemaking, it has been shown that cutting intensities and stirring speed respectively affect curd grain size and curd shattering. Decreased cutting intensity and increased stirring speed significantly increase the loss of fines and fat into the whey, thereby reducing cheese yields. Hence, it is important to monitor and optimize cutting intensity and stirring speed in a plant to maximize cheese yields.

Conclusion

The composition of milk, standardization of cheese milk and cheese making operations that minimize fine losses and increase recovery of fat and protein all contribute to the yield of cheese.