Mozzarella Cheese Manufacture

Provided by ADPI Center of Excellence member Dr. Nana Farkye, this article takes a look at the market information, standards and manufacturing methods, yield, shelf-life and freezing and functionality of mozzarella cheese.

Market Information

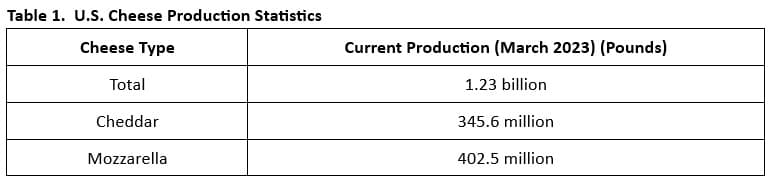

Mozzarella cheese is the largest single cheese produced by volume in the U.S. Current USDA statistics show that it accounts for over 30% of the total cheese produced in the U.S. (Table 1). (https://usda.library.cornell.edu/concern/publications/m326m1757).

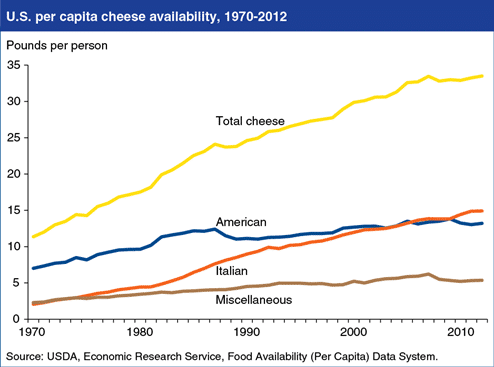

In 2021, the per capita consumption of Mozzarella cheese was 12.28 lb – growing steadily since 2009 when the per capita consumption of Mozzarella cheese overtook that of Cheddar (Fig. 1) (https://www.ers.usda.gov/data-products/dairy-data/dairy-data/) possibly due to increased growth in the popularity and consumption of Mozzarella as a pizza topping and snacking on string cheese.

The global market of Pasta filata cheese is about US$55 billion with the U.S. accounting for about the 57% of the global cheese). Pasta filata cheese sales have risen approximately 2% per year worldwide and are projected to increase to $65.01 billion by 2028. The global market for Mozzarella cheese estimated at US$37.3 billion in 2022, is projected to reach US$60.5 billion by 2030, growing at a rate of 6.2% over the analysis period 2022-2030.

Standards and Manufacturing Methods

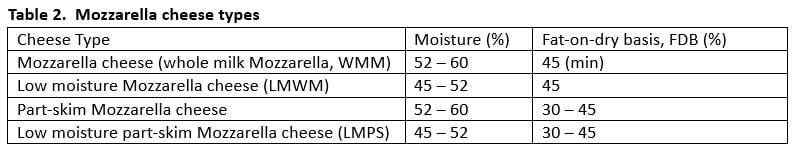

Mozzarella (or Scarmoza) cheese belongs to the group of pasta filata cheeses. Pasta filata is derived from an Italian phrase that literally means “spun paste” or “stretched curd”. Mozzarella cheese is a soft or semisoft cheese that is consumed fresh or after a short period of ripening. U.S. standards of identity (SOI) describes four principal types of Mozzarella cheese based on the moisture and fat-on-dry basis (FDB) contents as tabulated in Table 2 (21 CFR Part 133.155 to 133.158).

There are other forms of Mozzarella cheese, e.g., reduced-fat Mozzarella, shredded Mozzarella, Mexican Oaxaca (pronounced Wa-ha-ka) cheese and fresh Mozzarella (shaped as a ball and packed in weak brine). Fresh Mozzarella cheese is sold in different size balls/shapes (e.g., ciliengini and bocconcini). Mozzarella-type cheeses are also commercially available as string cheese and pizza cheese.

Mozzarella is a fresh soft cheese. USDA specifies that Mozzarella cheeses shall be aged no less than 5 days at 38°F to 42°F (3.5°C to 5.5°C) prior to inspection unless the cheese is shredded or diced and frozen. If the shredded or diced cheese is not frozen immediately after manufacture, the cheese shall be stored at 38°F to 42°F (3.5°C to 5.5°C) until frozen.

The manufacture of SOI Mozzarella cheeses involves standardization of cheese milk to casein to fat ratios (C/F) between 0.7 (for WMM) to 1.2 (for LMPS). The standardized cheese milk is pasteurized prior to Mozzarella cheese making using direct acidification (DA) or culture acidification (CA) methods.

For Mozzarella cheese made by DA, cold and dilute organic acid is slowly metered and rapidly mixed into the milk to prevent localized coagulation of milk. Although the CFR specifies vinegar (5% acetic acid), other acids (e.g., citric and lactic), acid esters (glucono-delta-lactone, GDL) or carbonation with CO2 are used for pH adjustment of the pasteurized milk to pH 5.6-5.8 prior to rennet coagulation at ~95°F and cheesemaking. Acidification with CO2 has added benefits of enhancing milk quality by suppressing spoilage bacteria and no negative effects on whey quality. Rennet (chymosin) is added after pH adjustment of milk for rapid coagulation.

The type of acid used, and the acidification pH of milk before coagulation influences solubilization of calcium, cheese moisture content, yield, and cheese functionality. Decreasing acidification pH causes increased solubilization of calcium, increased hydration and higher moisture cheese. After acidification and renneting, the curd is cut and allowed to settle, heal and firm up for about 30 min before whey drainage. The curd is kneaded and stretched in hot water, hot salt (~6%) water, or by steam injection until it is smooth and free of lumps. The molten curd is cut, molded, and firmed by immersing in cold water or brine.

Cultured Mozzarella cheese is manufactured from milk standardized to a C/F ratio of 0.9 to 1.2 depending on the FDB target. The standardized milk is pasteurized and cooled to 88-90°F prior to cheesemaking. Cheese starter comprising primarily of thermophilic Streptococcus salivarius ssp. thermophilus (cocci) and Lactobacillus delbrueckii ssp. bulgaricus and/or Lactobacillus helveticus) are added. The cultured milk is coagulated with chymosin. The coagulum is cut, healed, cooked to the desired firmness. The whey is drained, and the curd “cheddared” to the desired pH of 5.2-5.4 before melting, kneading and stretching in hot water (with or without salt) or by steam injection. Typical stretching water temperature is ~167°F with curd temperature of ~ 125 – 140°F. When the free-flowing molten cheese is pulled and stretched under the hot water, the proteins align resulting in a stringy chicken breast-like, fibrous texture of Mozzarella cheese.

The operational conditions of Mozzarella cheese mixer/molder influence cheese yield efficiency. Cheese yield efficiency increases with increasing stretching temperature and decreasing screw speed due primarily to changes in fat recovery in cheese. Increasing screw speed of the mixer/molder (5 to 19 rpm) decreases cheese moisture and increases fat loss. Fat loss decreases with decreasing mixer temperature (130 – 150°F).

Although low cooking temperature is desirable for Mozzarella cheese, food safety reasons necessitate operating cooker/stretcher machines at high temperatures. Stretching for 5 min at 150.8°F or at 170.6°F for 1 min decreases the cell density of L. monocytogenes by about 7 log cycles suggesting that the stretching process is an important biological control point during Mozzarella cheese manufacture.

Yield

Cheese yields depend on the efficient recovery of milk solids (fat and protein), the amount of salt added to the cheese and the moisture retained during cheesemaking. Fat content in milk significantly affects fat recovery, but not the percentage of nitrogen recovery, in the cheese and whey. The lowest and highest fat cheeses (5 and 25% fat, respectively) retained a lower percentage of total fat in the cheese and, therefore, lost a higher percentage of total fat to whey than did the medium fat cheeses (10 and 15% fat).

The percentage of total fat loss in the stretching water decreased as the fat content of the cheese decreased. The target fat recovery in the cheese for Mozzarella cheese yields is 85% compared to 93% for Cheddar cheese.

The typical yield of Mozzarella cheese made from milk standardized to casein to fat ratio of 1.1 (without solids fortification) is about 9.5%. However, to improve cheese throughput in a plant, manufacturers use high solids milk fortified with milk UF skim milk or UF whole milk while maintaining the desired C/F ratio. Click here to view the Federal register on rules for using UF milk in cheesemaking.

Shelf-life and Freezing

The shelf life for optimal functionality is about 30 days for fresh (high moisture) Mozzarella packed in preserving fluid or about ≥45 days for LMPS Mozzarella used for pizza topping. Extended storage (e.g., >60 d at 39.2°F) of LMPS mozzarella impairs functionality because the shredded cheese tends to clump together and ball up. When Mozzarella cheese past its optimal shelf life is used on pizza, the baked cheese exudes excess free oil with a “soupy” consistency resulting from proteolysis.

Because Mozzarella cheese has a relatively short shelf life and must be transported from where it is manufactured to the destination of use, the cheese is often frozen to extend shelf life to about 12 months. However, the frozen cheese must be used within 7 days after it is defrosted for optimal performance. The freezing point for Mozzarella cheese ranges from 23°F to 29.8°F, depending on the moisture, solutes in cheese, added salt and age of the cheese. Freezing affects cheese structure because not all the moisture in Mozzarella freezes. The free water in the cheese undergoes phase change and thermal expansion causing dehydration of the protein network. The rate at which the cheese is cooled to the freezing point and the time to completely freeze the core influences the extent of structural damage. Hence, it is best to completely freeze Mozzarella cheese in less than four hours suggesting the importance of the size of the size of cheese to be frozen. Individual quick freeze (IQF) technology using cryogenic fluids such as liquid N2 or CO2 is used to freeze Mozzarella cheese comminuted into small sizes in 10 minutes or less.

Freezing influences proteolysis of Mozzarella cheese during thawing and affects the functionality of thawed cheese. Frozen Mozzarella must be thawed in a refrigerator for 72 hours at 35 °F (best) to 41 °F (maximum) in its original package to prevent moisture loss. Slow thawing of the cheese is best. Tempering of previously frozen and thawed Mozzarella cheese for about two weeks is desired to improve its meltability and stretchability.

Functionality

Traditionally, LMPS Mozzarella requires 7-21 days storage at refrigeration temperatures for optimal functionality and baking quality. For pizza baking, LMPS and LMWM mozzarella perform best when the age of the cheese is between 14 days and less than 60 days of age. After this time, the uncooked cheese will start to soften and will be difficult to cut and shred, and the cooked cheese will start to break down and tend to flow excessively and suffer from weak body and lack of stretch.

Factors that affect cheese functionality include heat treatment given to milk, cheese chemistry – moisture, lactose content, pH) and fat globule size. The use of highly heated milk reduces cheese melt and stretch. Mozzarella cheese with high fat content and large fat globule size have higher meltability than cheese with small fat globules and lower fat content. Hence, homogenized milk cheeses have poor meltability. The pH of curd at stretching affects cheese functionality. Optimum stretching pH is 5.2 – 5.4 for curd made by CA whereas optimal stretching pH of Mozzarella cheese made by DA is about 5.7. This is related to the level of demineralization of calcium from the curd. Mozzarella cheese curds stretched at 149°F has a higher meltability than curds stretched at 185°F. Oiling-off of Mozzarella cheese in pizza is an important attribute. However, excessive oiling-off is undesirable. High oiling-off is associated with larger fat globules and a higher degree of proteolysis. Excessive levels of reducing sugar (i.e., residual lactose and galactose) affect browning on baked cheese. Galactose accumulates in cheese made with S. thermophilus because this organism does not metabolize galactose. Therefore, Lb. helveticus is used to instead of S. thermophilus to control the level of galactose in cheese.

Salt content affects Mozzarella cheese functionality. During Mozzarella cheese making, the hot cheese from the cooker/stretcher is molded and placed in a cold brine solution where it cools down and takes up salt. After brining, the salt is concentrated on the outside of the block. Depending on the size of the block, it takes about 7 to 10 days for the salt to become evenly distributed throughout the cheese. Hence it is important to not use Mozzarella cheese that is too fresh (i.e., less than 10 days old).

With the continuous growth in the consumption of pizza, other convenient foods like quesadillas and dishes that require melted cheese functionality, the demand for Mozzarella cheese production and consumption will continue to grow.

Selected References

Barbano, D.M., A. Renda, J.J. Yun, and P.S. Kindstedt. 1994. Influence of cheese temperature and screw speed on Mozzarella cheese yield. Proceedings from the 31st Annual Italian and Specialty Cheese Seminar. Sept 18 & 19, 1994.

Dairy Products. ISSN: 1949-0399. Released February 3, 2023, by the National Agricultural Statistics Service (NASS), Agricultural Statistics Board, United States Department of Agriculture (USDA). Accessed May 2023.

Francolino S., F. Locci, R. Ghiglietti, R. Iezzi, G. Mucchetti. 2010. Use of milk protein concentrate to standardize milk composition in Italian citric Mozzarella cheese making. LWT – Food Science and Technology 43:310–314.

Fusco V., D. Chieffi and M. De Angelis. 2022. Invited review: Fresh pasta filata cheeses: Composition, role, and evolution of the microbiota in their quality and safety. J. Dairy Sci. 105:9347–9366.

Global Industry Analysts, Inc. 2023. Mozzarella Cheese: Global Strategic Business Report. https://www.researchandmarkets.com/reports/5301624/mozzarella-cheese-global-strategic-business. Accessed May 2023.

Kim J., K. A. Schmidt, R. K. Phebus, and I.J. Jeon. 1988. Time and temperature of stretching as critical control points for Listeria monocytogenes during production of Mozzarella cheese. J. Food Protec. 61: 116-118.