Resource &

Knowledge Center

Milk Ingredients

Whey Ingredients

CARBOHYDRATE INGREDIENTS

milkfat Ingredients

Dry Milks | Overview

When the majority of moisture is removed from milk, the result is dry milk. Moisture content for dry milk is usually less than 5%. So think of dry milk ingredients as authentic milk products with a greatly extended shelf life. The two most common types of dry milk ingredients are whole milk powder (WMP) and nonfat dry milk (NDMNonfat dry milk More). Advances in processing technology and equipment have resulted in a growing range of tailor-made dry milk ingredients including low-sodium and instantized.

Grade “A” dry milk product must be produced with Grade “A” milk in a Grade “A” plant. All other parameters for Grade “A” products are the same as “Extra Grade.”

Caseins | Overview

Caseins are highly functional and nutritious proteins, with applications that span a broad range of food, beverage, and industrial applications owing to their special properties. All caseins begin with a precipitation or coagulation step, using acid or enzymes to recover the caseinProtein in milk that precipitates at pH 4.6. More proteins from milk as a solid, which is subsequently washed and dried to yield a stable powder. These caseinProtein in milk that precipitates at pH 4.6. More powders themselves have very limited water solubilityAbility of a liquid to dissolve another material. Examples: Lactose dissolving in water, alcohol dissolving in water. More in their acid or rennet forms, but when converted to a caseinateAcid or rennet casein that has been treated with alkali to make it soluble in water. The exact alkali used determines the functional properties of the resulting caseinate. More salt, they become highly water soluble and therefore suitable for a broader range of end uses. The most commercially common caseinateAcid or rennet casein that has been treated with alkali to make it soluble in water. The exact alkali used determines the functional properties of the resulting caseinate. More forms are calcium caseinateAcid or rennet casein that has been treated with alkali to make it soluble in water. The exact alkali used determines the functional properties of the resulting caseinate. More, potassium caseinateAcid or rennet casein that has been treated with alkali to make it soluble in water. The exact alkali used determines the functional properties of the resulting caseinate. More, sodium caseinateAcid or rennet casein that has been treated with alkali to make it soluble in water. The exact alkali used determines the functional properties of the resulting caseinate. More, and ammonium caseinateAcid or rennet casein that has been treated with alkali to make it soluble in water. The exact alkali used determines the functional properties of the resulting caseinate. More, depending on the neutralizingAddition of caustic, such as sodium hydroxide, to increase the pH of the product. Neutralizing typically would be used only for acid or fermented whey. More agent that is chosen for conversion.

Dry Milk Products Standards

ADPIAmerican Dairy Products Institute More Standards promote the production of uniform, high-quality dry milk products. In addition, they serve to protect the manufacturer of superior qualityFocus on doing things well and producing a product acceptable to consumers More products from competition by inferior products and provide a basis for an effective qualityFocus on doing things well and producing a product acceptable to consumers More control program. If the fluid milk supply, it’s processing, and the subsequent storage of the finished product are in accordance with acceptable procedures and practices, the dry milk product offered should meet these industry standards. Composition specifications included with these standards will help determine general overall product excellence.

These composition requirements are not designed to meet all end-uses. Consequently, to determine the acceptability of the product for a specific use, special supplementary tests not included in these standards may be necessary. However, buyers who use these standards in their purchases provide themselves with an added safeguard regardless of the particular purpose for which the product may be intended.

Grading Requirements of Dry Milk Products

Grading Requirements for Nonfat Dry Milk (NDM), Instant Nonfat Dry Milk INDM), Dry Whole Milk (DWM), Dry Buttermilk (DBM) and Dry Buttermilk Product (DBMP) were developed to promote the utilization of these products by making available a uniform grading system for EXTRA GRADE and STANDARD GRADE products. Both manufacturers and purchasers utilize these grading standards for the following reasons:

- Assure Uniformity: Uniform qualityFocus on doing things well and producing a product acceptable to consumers More of product is assured by grade specification, accepted and understood throughout the dry milk industry. Dry milk product standards enable both manufacturers and purchasers to specify the grade of product offered for sale or required for use.

- Facilitate Purchase: Buyers and sellers are afforded a common basis whereby a dry milk product, meeting definite product requirements, is recognized by its grade name. Tests and grades are based on accepted specific analytical procedures, well understood by both parties. In this way, many detailed tests varying between manufacturing and purchasing organizations are eliminated.

- Reduce Risk: The manufacturer of the dry milk product assumes the responsibility for delivering the grade of product offered. Any elementA spiral-wound membrane More of risk is eliminated from the purchase since the buyer may have each purchase checked by grade analysis. Similarly, the manufacturer is protected against unreasonable complaints because the grade standards are succinct and based upon specific methods of analysis.

How to Choose between a Milk or Whey Ingredient

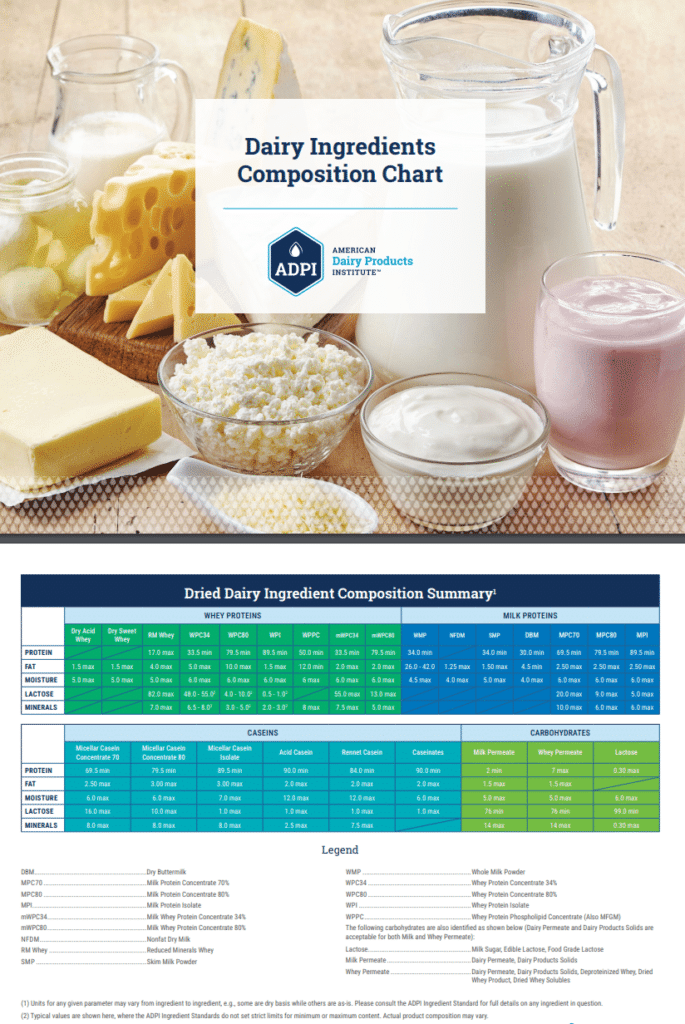

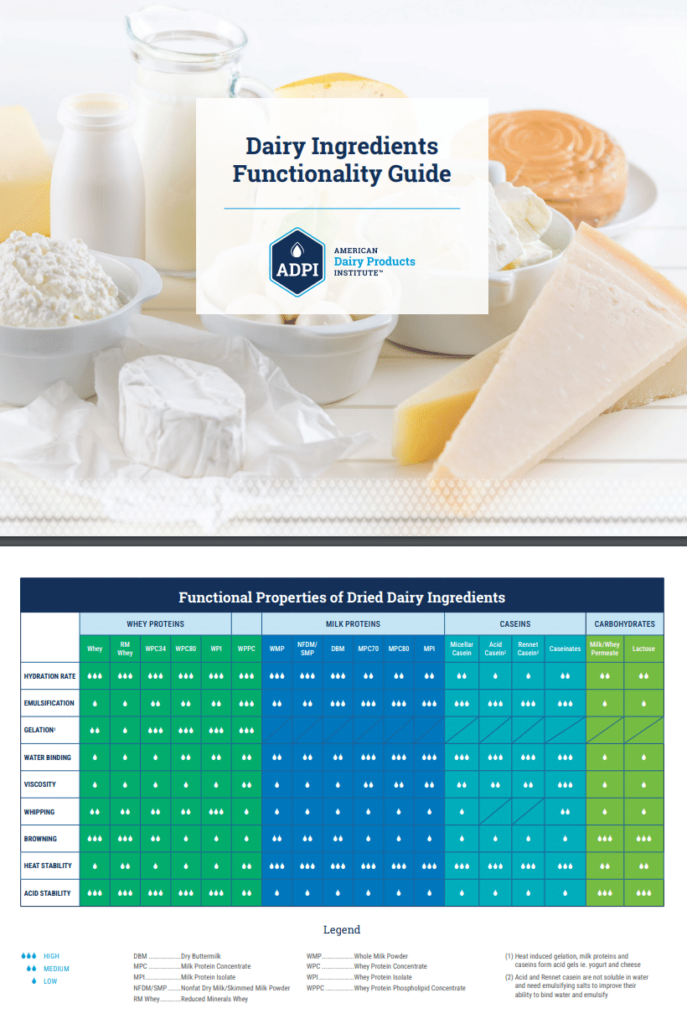

Milk and wheyLiquid obtained from cheese manufacture. More ingredients provide multiple benefits to food products. These benefits are often described as flavor, function, and nutrition. They provide a mild, dairy flavor that blends well with many food products. Their composition can consist of multiple components such as, proteins (caseins and/or wheyLiquid obtained from cheese manufacture. More proteins), milkfat, lactose, and ashResidue that remains when milk/whey is heated to very high temperatures in a muffle oven. Organic acids are lost during ashing. Some minerals such as sulfur and phosphorous also may be lost. Other minerals may be converted to oxides, sulfates, phosphates, silicates and chlorides. In general, ash overestimates the concentration of minerals present since oxygen is combined with minerals in the remaining ash. The term often is used interchangeably with minerals and milk salts. (mineralsGenerally refers to elements other than carbon (C), hydrogen (H), oxygen (O) and nitrogen (N) that are found in dairy products. The term often is used interchangeably with salts and ash. More), and thus provides many different functional properties described in the table below. These components also provide many of the same unique nutritional properties found in milk.

Milk and wheyLiquid obtained from cheese manufacture. More ingredients are used in a wide variety of food products including dairy products, baked products, confections, soups, sauces, infant formula, processed meats, prepared foods, and beverages. Selecting the right dairy ingredient for your application can be confusing because many milk and wheyLiquid obtained from cheese manufacture. More ingredients have a similar composition, for example nonfat dry milk (NDMNonfat dry milk More) and whey proteinProtein in milk that remains in water phase after casein precipitates. More concentrate 34 (WPC34). Even though the protein content is about the same, NDMNonfat dry milk More consists of roughly 80% caseinProtein in milk that precipitates at pH 4.6. More and 20% whey proteinProtein in milk that remains in water phase after casein precipitates. More, while WPC34 is all whey proteinProtein in milk that remains in water phase after casein precipitates. More. Often the choice is made based on price, but comparing the differences in functionality is probably the most important method of selection.

SolubilityAbility of a liquid to dissolve another material. Examples: Lactose dissolving in water, alcohol dissolving in water. More in water is the single most important functional property for a milk or wheyLiquid obtained from cheese manufacture. More ingredient. No matter which ingredient you choose, it must be soluble for it to be functional. The solubilityAbility of a liquid to dissolve another material. Examples: Lactose dissolving in water, alcohol dissolving in water. More of a milk or wheyLiquid obtained from cheese manufacture. More ingredient that contains protein is impacted by the pHA measure of the acidity or alkalinity of a material. The pH scale ranges from 0 (acid) to 14 (alkaline) with 7 considered neutral. pH is a measure of the concentration of hydrogen ions and is defined as the negative log of the hydrogen ion concentration. More of the food. Milk protein ingredients have good solubilityAbility of a liquid to dissolve another material. Examples: Lactose dissolving in water, alcohol dissolving in water. More above pHA measure of the acidity or alkalinity of a material. The pH scale ranges from 0 (acid) to 14 (alkaline) with 7 considered neutral. pH is a measure of the concentration of hydrogen ions and is defined as the negative log of the hydrogen ion concentration. More 6.0. Whey proteinProtein in milk that remains in water phase after casein precipitates. More ingredients have good solubilityAbility of a liquid to dissolve another material. Examples: Lactose dissolving in water, alcohol dissolving in water. More at pHA measure of the acidity or alkalinity of a material. The pH scale ranges from 0 (acid) to 14 (alkaline) with 7 considered neutral. pH is a measure of the concentration of hydrogen ions and is defined as the negative log of the hydrogen ion concentration. More 3-7. Lactose, the main component in the ingredients lactose and milk/whey permeate (dairy products solids) has good solubilityAbility of a liquid to dissolve another material. Examples: Lactose dissolving in water, alcohol dissolving in water. More below a concentration of 14% in room temperature water, but has lower solubilityAbility of a liquid to dissolve another material. Examples: Lactose dissolving in water, alcohol dissolving in water. More (will crystallize) at refrigeration temperatures. The solubilityAbility of a liquid to dissolve another material. Examples: Lactose dissolving in water, alcohol dissolving in water. More of dairy ingredients that are high in calcium (such as milk/whey permeate), decrease with heat treatment and at a pHA measure of the acidity or alkalinity of a material. The pH scale ranges from 0 (acid) to 14 (alkaline) with 7 considered neutral. pH is a measure of the concentration of hydrogen ions and is defined as the negative log of the hydrogen ion concentration. More greater than 5. These are the primary characteristics to help select the right dairy ingredient for your application.

Functional Benefits of Milk & Whey Ingredients

| Function | Primary Components | Benefits |

|---|---|---|

| Solubility | Protein | Provides better performance in all applications |

| Browning | Protein and Lactose | Provides color and flavor development |

| Emulsification | Protein-caseins provide stronger emulsification than whey proteins | Provides binding and separation of fat globules and texture stability |

| Heat Stablity | Protein-caseins are more heat stable than whey proteins | Prevents protein aggregation and settling for properly hydrated ingredients during high heat processing |

| Gelling & Heat Setting | Protein-whey proteins will denature and form gels with heat treatment | Provides structure and water holding properties |

| Water Binding & Viscosity Building | Protein-caseins have more water binding ability than whey proteins | Improves texture and mouthfeel; Helps to retain moisture and improve shelf life |

| Whipping & Foaming | Protein-whey proteins generally foam more than caseins | Provides aerated structure and texture |